The platter

The job of a turntable or record player is essentially very simple. It has to convert the sound vibrations mechanically recorded on a piece of vinyl into an electronic signal.

Musical information is encoded onto a record in a spiral pattern from the outside in. Therefore, in order to decode this information, the record must be spun and the information within the spiral read.

The record has to be spun at the same speed as it was when the vibrations were originally carved into the master disc, otherwise the music will play either too fast or too slow. This is usually 33 ⅓ or 45 revolutions per minute.

To learn more about how records are made in the first place, you can read our article here.

The turntable must be able to maintain this constant speed without fluctuation, otherwise you will be able to hear the minute differences as wow and flutter while the record slightly speeds up and slows down. Our ears are very sensitive to this type of distortion. If you want to test your record player for performance in this area we recommend playing some solo piano music – any wow and flutter will quickly become very obvious!

It is also important that the platter on your turntable is able to spin silently without introducing any vibrations of its own. Quiet electric motors are generally used to assist with this, as well as carefully designed bearings, and even suspension systems to provide isolation on some more exotic models.

Once your turntable is able to spin your vinyl smoothly and silently, the next step is to make sure that the needle is in the right place. This is the job of the tonearm.

The tonearm

The tonearm has a very important job to do. It must ensure that the ‘decoder’ or needle of your turntable is held in the right place at the right time. It has to be stable, free-moving, non-resonant, strong and light.

At one end of the tonearm is a cartridge which holds your needle or stylus and contains the electromechanical components that turn physical vibrations into an electrical signal.

At the other end is a system of bearings and counterweights to allow the tonearm to pivot and track the groove on your record smoothly with just the right angle and amount of pressure.

Tonearms are usually tubular structures and are commonly constructed from materials such as aluminium, wood, cork, or carbon fibre.

Cartridges and styli

The business end of any turntable – the stylus and cartridge are what really make the music happen.

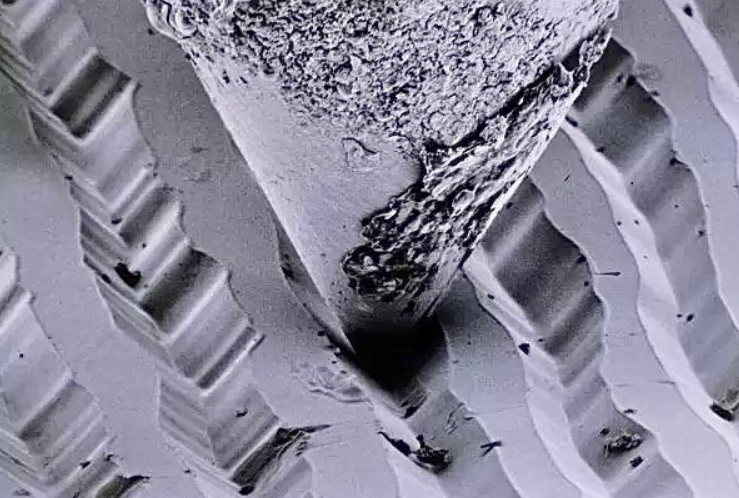

The turntable stylus and cartridge are the two components responsible for transforming mechanical vibrations from a vinyl record into an electrical signal. The stylus is the needle-like device that is placed in the record groove. Styli are typically made from aluminium or more exotic materials such as boron and are tipped with a hard mineral such as sapphire or diamond. The cartridge is the device that the stylus attaches to and converts the mechanical vibrations of the stylus into an electrical signal.

Inside a moving magnet (MM) cartridge, a tiny magnet is attached to the end of the stylus. As the stylus vibrates it causes the magnet to move within a coil of wire. This moving magnetic field creates a weak electrical signal in the wire that will be boosted by your phono stage and amplifier before being fed to your playback device. A moving coil (MC) cartridge works in much the same way, except this time the magnet is fixed to the body of the cartridge and a tiny coil of wire is attached to the vibrating stylus. This reduces mass from the stylus assembly and makes it nimbler than the MM variant, the electrical signal produced is even weaker however and requires even more boosting.

As you can imagine, with such miniscule electromechanical parts expected to read 1000km (621mi) of musical information over their lifetime – the average diamond stylus lifespan – they need all the help they can get.

Have your records cleaned professionally today, free them from abrasive matter and revive your sound!