Manufacturing process

To fully understand how vinyl playback works we must first start with how they’re made.

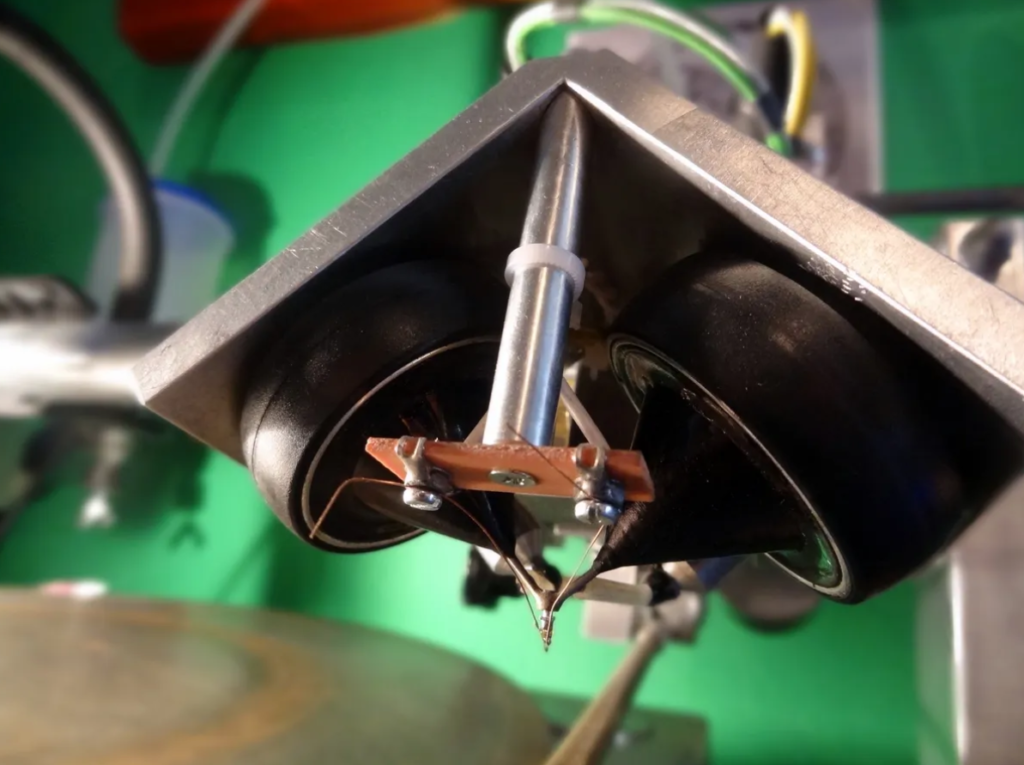

Vinyl records are made via a process called vinyl mastering and pressing. First, the audio is transcribed (historically from magnetic master tapes) onto a master disc, which is usually made of lacquer or copper. This process takes place on a disc cutting lathe: The audio signal is fed through a cutting amplifier to the cutting head which engraves a modulated spiral groove corresponding to the audio signal into the surface of the master disc.

This master disc is then electroplated in order to capture the relief of the engraved grooves. The completed metal disc after this stage is called the stamper. Two master discs and subsequently two stampers are made for each vinyl record – one for each side. Each stamper is good for about 1000 record pressings before it starts to wear to the point of affecting sound quality. Multiple stampers can be made from each master disc to replace those that wear out.

To press vinyl records, pellets of PVC are melted into a puck which is placed between the two hot metal stampers. A lubricant and a mold release agent are applied to help the molten vinyl flow across the mold into all of the grooves and to enable the removal of the record at the end of the process. Residues from the manufacturing process remain on the final product when it is packaged – there simply isn’t time to painstakingly clean each record leaving a busy pressing plant.

Playback

When you go to play a record, you move your turntable’s tonearm to the outer edge of the spinning record and drop the needle; the music starts playing.

What is actually happening here is that mechanical vibrations transcribed into the vinyl are being turned into electrical signals. These are then increased by your amplifier and fed to your speakers which convert the signals back into mechanical vibration at a greater amplitude.

To extract and convert the mechanical vibrations recorded in vinyl your turntable uses some very finely-tuned parts. We have another article here that goes into more detail on how this works.